LG-550 Oblique Cutting Machine

Litekanyetso tsa tekheniki le tlhaloso:

1. Sekhahla sa likarolo: Kenya kopano ea thipa ea arc ho khaola stems le lisebelisoa tse ling, bolelele ba karolo ke 2-30, haeba bolelele ba karolo e le 10-60mm, motlakase oa spindle o fetotsoe ho tloha 0.75kw-4 ho 0.75kw-6.

2. Ho khaola: Kenya mochine o hlophisitsoeng oa hlooho ea seha ho khaola lithupa le makhasi, 'me sebopeho sa block ke 10 × 10 ~ 25 × 25. Haeba u hloka ho khaola ho feta 20 × 20, kenya maske a fensetere ea fensetere ea sekheo, koahela e le 'ngoe. ea lifensetere, le ho khaola ka fensetere e le 'ngoe.

3. Shredding: Kenya sebaka sa kopano ea hlooho ea sehahi, 3 × 3 ~ 8 × 8, terata, hlobolisa le mataese ka bolelele bo ka tlase ho 30.f

4. Miter Cutting: Fetola angle ea ho kenya pakeng tsa sehahi le sejana sa phepelo ho khaola 30 ° ~ 45 ° bevel, e arotsoe ka mefuta e 'meli: e otlolohileng le ea ho itšeha.

5. Bolelele ba ho itšeha: Hangata spindle ke 810 rpm, 'me sekoti sa phepelo se tsamaisoa ke motlakase o laolang lebelo la motlakase oa 0.75kw kapa mochine o fetolang maqhubu ka 1: 8.6 lebokose la ho fokotsa le pulley.U hloka feela ho fetola konopo ea lebelo la lebelo ho fumana bolelele ba ho itšeha.

6. Sephetho: 1000 ~ 3000kg / h

7. Ponahalo: 1200 × 730 × 1350, ho fepa ka 200 × 1000.

8. Boima: 220kg

Litaelo tsa tšebeliso le litemoso:

(1) Mochine o na le sesebelisoa sa tšireletso, enjene e sebetsa ka mokhoa o tloaelehileng, 'me lemati le bulehile.Ho baleha lebelo le leholo la lehare.

(2) Lehare sila e lokela ho ba bohale, thipa le thipa bohale tumello bakeng sa tlhomamiso le tokiso ea 0.5 ~ 2.0mm.

(3) Holimo le tlase boemo ba lebanta la conveyor le tlameha ho lokisoa bohareng ba conveyor, ho tiea ha sekoti sa selemo ho loketse.

(4) Fepa layer e lokela ho ba e boreleli le e makhethe, e tsitsitseng haholo le e tsoelang pele ea ho fepa e thekesela e ka finyella sebopeho se setle sa lijo-thollo, sekoahelo se makhethe.Bolelele ba tumellano.

(5) Lisebelisoa tsa ho itšeha li lokisoa, sesebelisoa sa motlakase se khaotsoe, 'me molao oa lebelo ha o hlokehe ho khutlela ho zero.

(6) Hangata hlokomela hore thepa e ke ke ea khomarela lebanta la conveyor ka hare le holim'a rolara, hang ha sehlahisoa se tla ama sebopeho sa karoloana, kapa se khaole lebanta la conveyor.Hang ha karete e kena, hang-hang khaotsa ho hloekisa, hangata lihora tse 4 ho hloekisa.

(7) Ts'ebetso ea mochini e tlameha ho leka-lekana, joalo ka ha ho sibolloa ha vibrate ho lokela ho hlahlojoa.Ho seng joalo, e tla ba meter e mpe ea lebelo kapa kotsi e sa sireletsehang.

1) ho seha poleiti, poleiti:

A, fektheri e nang le kopano e ntle ea thipa ea arc (sheba setšoantšo).Ka lebaka la ho roala lisebelisoa le ho thothomela, ho ka eketsa kapa ho fokotseha ka gasket.

B, likotoana tsa bobeli tsa thipa ea arc boemong ba boima, sehiloeng sa pele, tekanyo ea thipa ea bobeli.Pele le ka mor'a thipa tse peli li lokela ho sebelisoa ho fapanyetsana, e le ho thibela e 'ngoe ea ho senya ho leka-lekana.

2) karolo ea sehiloeng ka thipa habeli, sengoathoana (bona setšoantšo).

(8) Seha sebopeho, terata seha sebopeho ka kopano tloaelo.Motho ya sehang

Kopano e entsoe ka motsoako oa aluminium, thipa e sehang ea tšepe e sa hloekang, thipa, thipa, pad e phahameng ea aluminium alloy pad, polasetiki ea polasetiki, mask.The cutter sehiloeng 25mm ka holim'a thepa e ngata, fektheri e tla kenngoa ka tekanyo e ntle ea mask.

Sekha sa boholo: bophara = thipa lijo-thollo sebaka, bolelele = bolelele (ka ho fepa conveyor lebelo sete).

Thipa lijo-thollo bapala qetellong ea noutu e moholo ho feta kapa lekana le ho romela seretse qetellong ea mola, ba bang kaofela ba lijo-thollo seha sekgeo ho ea ka ditlhoko tsa tlhaloso ba ka tsela e tšoanang ajoa le ho hlophisoa, ho seng joalo lihlahisoa tse mpe eketseha.

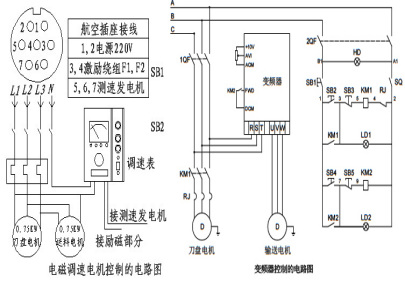

Motlakase oa lebelo la motlakase oa motlakase le mokhoa oa ts'ebetso

(1) Mohala: bakeng sa terata e meraro ea mekhahlelo e mene, mohala o mofubelu (o motala) o kopantsoeng le motlakase oa mekhahlelo e meraro, mohala o le mong o mosehla oa zero.

(2) Qala: tobetsa konopo e tala ea ho qala, ts'ebetso ea thipa ea disk, ho ea ka molaoli oa toggle switch (ho phunyeletsa), ho laola knob angle, ke hore, ho fetola bolelele ba ho itšeha.

(3) Emisa: ka lehlakoreng le fapaneng konopo ea tokiso e fetohela ho zero, tobetsa konopo ea toggle switch (ho tima), tobetsa konopo e khubelu ho emisa.

Inverter control wiring le mokhoa oa ts'ebetso

(1) Mohala: tsamaiso ea terata ea mekhahlelo e meraro, ho na le mohala o motala o mosehla o nang le mebala e 'meli o pepesitsoeng ka lebokoseng la taolo, mohala ona ke ho sireletsa fatše, mochine o kenngoe, o tlameha ho ba fatše, ho seng joalo moetsi o tla ikutloa a le moferefere. .

(2) Qala: ho ea ka konopo e tala qala ho switjha ho seha hlooho enjene mathang ho bula inverter switjha ho lokisa inverter knob, ke hore ho fetola ho itšeha bolelele.

(3) Emisa: tobetsa konopo e khubelu ea ho emisa.

Bearing, tiiso ea oli

(1) Main shaft behang: 2073 lihlopha;tiiso ea oli: 3558122

(2) Lebantang la conveyor le tiisitsoeng habeli: li-sets tsa 1802045

(3) Phokotso ea li-gear box bearing: 2054 li-sets, lihlopha tsa 2062;tiiso ea oli 2542104, 3045102;the bridge shaft outer spherical bearing: P205 1 set