Mochini oa ho qoelisa ka litholoana le meroho oa LG-350

Tekheniki Parameters

a.Propeller bophara: 350 limilimithara

b.Motor : Y112M-44KW

c.Bokhoni: 1000-2000kg/h

d. Boima: 350kg

d.Dimensions: 1100x 1100 x1600mm (bolelele * bophara * bophahamo)

e.Feed inlet: bophahamo ba seketsoana ho tloha fatše1310mm sebakeng sa 450×360mm

f.Boema-kepe ba ho lahla: bophahamo ba kantle ho tloha sebakeng sa kantle sa 490mm sa 195× 60mm

Molao-motheo oa ho sebetsa

Ho tloha ho lisebelisoa tse tala ho ea ho hopper ho ea ho potoloha ha propeller, sehlahisoa se tlas'a ketso

ea matla a centrifugal, haufi le lehlakore le ka hare la khetla e ka ntle, ka mahare a propeller ka ho seha

thipa, 'me haufi le thipa e sehang ho tloha monyakong o ka pele oa ntlo o ka fetolehang ho tsoa, selae botenya ka

ntlha ya lemati ya diphatlha tsa lehare la selae e tiisitsoe.Sela ka selae tataiso ho potoloha ha rolara ea ho fepa, ho fepa le ho potoloha ho amanang le

"Axiliary feed shaft", e tla romelloa ho "disk slice cutter shaft", lihlahisoa li khaoloa likotoana, ebe

ka ho toba ho potoloha ha thipa, khaola lisekoere tsa eona, khutlonnetsepa kapa tse ling tse seng li setiloe litekanyo.Likarolo: arola ka har'a li-roller tsa phepelo, eseng ho thibela sehiloeng, ts'ebetso.

Ho khaola boholo

Lokisa ho buloa ha lemati la ntlo, sebaka sa sebaka sa "disk cutter", 'me u nkele thipa sebaka

kopano.E ka khaoloa ka boholo bo fapaneng.1. Tlosa kopano ea thipa ea disc, kopano ea ho fepa e thusang le kopano ea thipa ea hlobolisa, lokisa

ho bula lemati la khetla, 'me e ka khaola selae sa 1.6 ~ 11mm.2. Kenya kopano ea thipa ea disk, kopano e thusang ea ho fepa, ntle le kopano ea thipa, e ka khaola strip, terata, sebopeho sa block.3. Kenya li-cutters kaofela

E ka khaola: 3 * 3 * 3, 3.5 * 3.5 * 3.5, 4 * 4 * 4, 5 * 5 * 5, 6 * 6 * 6 * 6, 7 * 7 * 7, 8 x 8 x 8, 10 * 10 * 10 tee

E ka boela ea khaoloa: 3 * 3 * (1.6 ~ 11), 3.5 * 3.5 * (1.6 ~ 11), 4 x 4 x (1.6 ~ 11), 5 * 5 * (1.6 ~ 11), 6 x6 x (1.6) ~ 11), 7 * 7 * 1.6 ~ (11), 8 x 8 x (1.6 ~ 11), 10 * 10 * (1.6 ~ 11)

Hape, bolelele ba silika bo bolelele ba 19, 25, 30 kapa mahala, le tsona li ka kopanngoa ho fokotsa botenya bo fokolang.

ho feta li-cubes tse 10 tse hlokahalang.4. Ho ea ka sesebelisoa motsoako ka khaola botenya ba fapaneng lisekoere sebopeho, rectangular hlobolisa, hlobolisa bolelele e ka ba 15, 20, 25, 30 kapa mahala bolelele.5. Tlosa kopano ea thipa, 'me thepa e ka khaoloa ka likhoele tse telele tsa mahala.6. Khaola likotoana tsa 3 × 3, 6 × 6, u arolelane litlhaloso tse tšoanang (3) kopano ea lijo tse thusang, moropa oa ho fepa.

le ho kopanya meno ka kama.Ho khaola likotoana tsa 4 × 4, 8 × 8, ho arolelana litlhaloso tse tšoanang (4) kopano ea lijo tse thusang, roller ea lijo le

kopano ea meno ea khekhe;

Ho khaola likotoana tsa 5 × 5, 10 × 10, ho arolelana litlhaloso tse tšoanang (5) kopano ea lijo tse thusang, li-feed roller le

kopano ya kama.

Kenya ts'ebetso

1.Boemo ba ho kenya thepa e lokela ho ba e le hore thepa e tsitsitse ebile e na le ho lekaneng

sebaka sa ho hloekisa le ho hlokomela ha bonolo.

2. Hokela motlakase e le hore propeller e potolohe ka tsela e fapaneng le oache ha e shejoa ho tsoa koung ea phepelo

mme e theilwe hantle.

3. Pele o qala sesebelisoa, hoa hlokahala ho etsa bonnete ba hore mekhatlo eohle e tsoang kantle ho naha le lihlahisoa tsa eona

sebaka sa ho fepa se tlositsoe, 'me disc ea letsoho e hokahanngoa le lebili la lebanta ho netefatsa

hore ha ho na 'mele osele ka har'a sesebelisoa sa ho seha.

4. Qala motlakase, etsa hore e fihle ka lebelo le feletseng la boemo ba ho sebetsa, bo tsitsitseng le junifomo ho tloha koung ea lijo

ho fepa.

Hlokomela:

(1) u se ke ua lumella lintho tse tsoang linaheng tse ling tse kang lisebelisoa, majoe, libotlolo le lisebelisoa tse ling sebakeng sa ho fepa, e le hore u se ke ua senya likarolo tsa mochine oa ho itšeha.

(2) U se ke ua tsoela pele ho ja ho feta tekano, e le hore u se ke ua tlatsa koloi e ngata, tšubuhlellano ea koung ea phepelo kapa ho itšeha.

sesebelisoa se khomaretsoeng, se amang boleng ba sehlahisoa.

(3) U se ke ua kenya letsoho la hao molomong oa phepelo, e le hore u se ke ua khaola letsoho.

(4) Ha thepa e ntse e sebetsa, sekoahelo sa sekoahelo kapa letlapa le sireletsang se ke ke sa tlosoa ho

qoba kotsi e mpe.

(5) Lehare le hlabang le tlameha ho leotsoa pele le ka sebelisoa hape.

Tlhokomelo

Mochine o na le li-cutters tse bohale, likarolo tse potolohang le matla a phahameng a matla.Ha u fetola lintlha tsa ho itšeha le ho boloka lisebelisoa, phepelo ea motlakase e tlameha ho khaoloa ebe e notlelloa

pele.Sekoahelo le poleiti ea tšireletso li ka tlosoa ka mor'a ho netefatsa ka pono hore thepa e emisitsoe ka ho feletseng, ho seng joalo kotsi e tebileng e ka bakoa.

(A) tlhokomelo ea letsatsi le letsatsi

1. Tlosa sekoahelo le poleiti ea balebeli bakeng sa tlhokomelo ea likarolo tsohle tsa thepa.

1) Tlosa sekoahelo sa sekoahelo, sekoahelo se sireletsang le sekoahelo sa tataiso ea karolo ho boloka kopano ea dicing

le ho tlotsa mochini.

2) Harola hopper ea phepelo ho boloka sesebelisoa sa ho seha.

3) Harola poleiti ea balebeli ho boloka karolo ea daese le karolo ea ho khanna.

2. Ho hloekisa: khaola le ho notlela phepelo ea motlakase, tlosa lipoleiti tsohle, 'me u hloekise hantle.

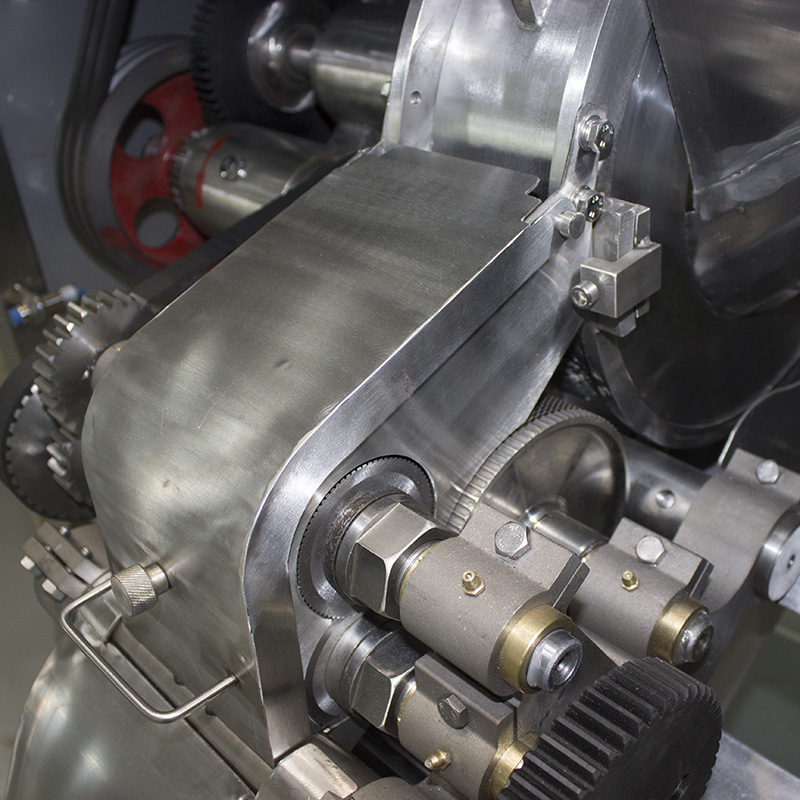

3. Lubrication: Lintlha tse 8 tsa koporo tsa mochini ona li na le oli ea koporo ea 'mabole.

li-nozzles (joalokaha ho bontšitsoe setšoantšong).Mafura a lijo a tlameha ho eketsoa hanngoe bakeng sa lihora tse 4 ~ 6 tsa ts'ebetso, le ho

ts'ebetso e tlameha ho bolokoa habonolo.Lisebelisoa tse sa reroang bakeng sa ho tlatsa mafura: 400g e tloaelehileng ea khatello ea mofuta oa botoro

sethunya.Likarolo tsa lisebelisoa hangata li tlotsoa.

(B) Tlhokomelo ea likarolo tsa bohlokoa le likaroloana

1. Ho qhaqhoa, ho hlahloba, ho hloekisa le ho kenya mochine oa ho qoela.

1) tlosa

a.Tlosa le ho notlela motlakase, tlosa phanele e ka pele, groove e se nang letho, tataiso ea karolo

sekoahelo, poleiti e sireletsang, 'me u tlose lebanta la synchronous.

b.Tlosa kopano ea lehare: lokolla sekoti sa ho lokisa holim'a lehare la lehare, tšoara kopano ea lehare, 'me u ntše spindle le gear.

c.Arola shaft ea "disk cutter": tlosa lebanta la synchronous, lokolla li-screws tsa gear ea nylon, tlosa lisebelisoa tsa phetisetso ea li-strip cutter, lokolla li-screws tsa shaft ea thipa, tšoara kopano ea "disk cutter" ka letsoho le le leng, 'me u ntše disc. cutter shaft le enngwe.

d.Tlosa shaft e thusang: lokolla screw ea ho lokisa ea shaft e thusang, tšoara

Auxiliary feed shaft assembly ka letsoho le le leng, ebe o hula shaft e thusang ka ho

tse ding.2) Tlhahlobo ea ho hloekisa:

Hloekisa hantle, hlahloba koranta le lesela la koporo hore na li felile, 'me u tlose meno a kama

le ho fepa barrel ha ho hlokahala.3) Kopanya hape:

A. Ha o kenya shaft, shaft e tlameha ho khona ho phunyeletsoa le ho potoloha ka bolokolohi.B. Kenya moropa oa phepelo: beha moropa oa phepelo bohareng ba litšehetso tsa mahlakoreng a mabeli, le

lekhalo pakeng tsa ntlha e le 'ngoe le sefahleho sa ho qetela sa liner ea koporo ke hoo e ka bang 0.1mm.Sututsa the

fepa drum shaft mme o tiise dikurufu tsa ho lokisa (hlokomela hore dikurufu tse pedi tsa ho lokisa di lokela ho wa

sekoting sa mokoting).

C. Kenya kopano ea li-disk cutter: sutumelletsa karolo ea "disk cutter shaft" ka har'a bracket e ka thōko, beha kopano ea "disk cutter" pakeng tsa lisebelisoa tse peli tsa koporo, lehare la disc le behiloe.

bohareng ba groove ea li-cylinder groove, ebe o sutumelletsa molamu ka hare, e le hore lekhalo pakeng tsa ntlha e le 'ngoe le sefahleho sa ho qetela sa liner tsa koporo le ka bang 0.1mm, tiisa tse peli tse tsitsitseng.

li-screws (ela hloko ho oela ka sekoting sa shaft).D. kenya auxiliary feed shaft assembly: the side of the auxiliary feed shaft parts into

li-scaffolds, kopano ea phepelo e thusang lipakeng tsa koporo e 'meli, e etsa lehare la khabone bakeng sa phepelo e thusang lipakeng tsa lehare la disc, ebe e kena sebakeng sa phepelo se thusang, lehlakoreng le leng hole le

sebaka sa koporo se ka bang limilimithara tse 0,1, likoti tse peli tse tsitsitseng (e-ba hlokolosi ho oela ka mokoting oa sekoti).e.Kenya kama: Kenya khekhe ea mokoti sebakeng se bohareng pakeng tsa disc

lehare, fetola shaft ea kama holimo ho fihlela ntlha ea kama e thetsa boloko ba spacer ea kopano ea disc cutter, 'me u tiise kepisi ea borakete e ka lehlakoreng ka matla a itekanetseng.f.Kenya kopano ea li-cutter: sutumelletsa karolo ea sehahi ka har'a bracket e ka thōko, beha kopano ea sehahi pakeng tsa lihlahla tse peli tsa koporo, ebe u phahamisa shaft ea ho khaola e le hore gear e tsamaisane le "disk cutter shaft gear".Sebaka pakeng tsa qetello ea sehahi le sefahleho sa ho qetela sa bushing ea koporo ke hoo e ka bang 0.25mm, 'me u tiise li-screws tse peli tsa ho lokisa (ela hloko sekoti.

ea moqomo).

2. Kopano ea kopano ea li-disc cutter, kopano ea phepo e thusang le kopano ea lehare

1) kopano ea "disk cutter" holim'a sekoti ho kenya gasket qalong, ebe o kenya lehare la "disk" le leng (lehare la thipa le lokela ho shebana le nqa e le 'ngoe) le gasket (litlhaloso tse fapaneng tse se nang letho, ho qala botenya ba spacer pakeng tsa gasket le thipa le thipa ke

li fapane, tlhokomelo e khethehileng e lokela ho lefshoa ha ho tlosoa kopano, li-gaskets ho ea ka tatellano ea pele e teng, eseng ho hloka taolo), 'me qetellong tiisa linate tsa clamp.

2) kopano ea phepelo e thusang: holim'a sets'oants'o sa seha ho qala ka mor'a gasket (e sa koaheleng lintlha tse fapaneng, botenya ba gasket ea ho qala bo fapane), e kentsoeng ka thipa ea disc, ebe o kenya gasket le lehare le tlatselletsang la ho fepa, ka tsela e fapaneng holim'a shaft. ea ho qetela ke

bakeng sa lehare la disc le ho qetela gasket (setšoantšo), ha tighten nut, ho boloka lehare la carbon bakeng sa phepelo e thusang meno a tšeletseng a ho lumellana.

3) kopano ea thipa: 3, 3.5, 4, 5, 6, 7 mm karoloana ea butyl ea thipa e ka har'a selikalikoe tse peli tsa ho fumana tse behiloeng holim'a sesebelisoa sa sesebelisoa, ha ts'ebetso e tla qala ho fumana selikalikoe qetellong ea screw tight, e etse. haufi le sehlooho se ka thipa phomola, 'me joale ka hloko sutumelletsa thipa ka sekotjana, thaba a

lesale la bobeli, butle-butle alternately tighten nut, empa eseng haholo.Ho kenngoa ha li-cutters tse 8 ~ 10mm ho tlameha ho etsa hore li-cutters li be teng ka thata botlaaseng ba setulo sa thipa ho etsa bonnete ba hore seipone sa 0.038mm se ke ke sa kenngoa ka har'a lekhalo le ka morao ho thipa.